Why Rebowl your Vertical Turbine?

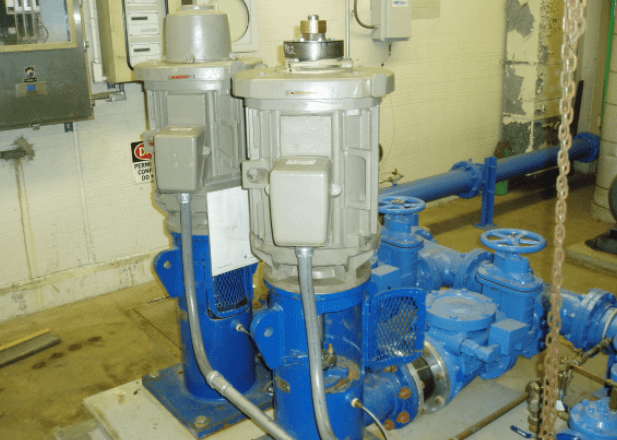

After years of continuous, heavy-duty service, the performance and operation of verical turbine pumps can decline. Often indicated by excessive vibration, cavitation and loss of head, pump fatigue is a costly condition resulting in increased power consumption and maintenance costs.

WASCON has teamed up with Peerless Pump to offer an extensive range of rebowl services that revitalizes the performance of vertical turbine pumps and reduces total pump operating costs. Whether restoring an aged pump or accommodating a change in operating conditions, customers are ensured high quality upgrades that focus on prolonging equipment life and improving safety.

WASCON has teamed up with Peerless Pump to offer an extensive range of rebowl services that revitalizes the performance of vertical turbine pumps and reduces total pump operating costs. Whether restoring an aged pump or accommodating a change in operating conditions, customers are ensured high quality upgrades that focus on prolonging equipment life and improving safety.

Rebowl Services Include

- Complete up-front inspection of all pump components

- Refurbishment of deteriorated components

- Upgraded replacement components

Materials upgrades

- Warranty on both service and parts

On-site installation service available

- Service for all makes and models

- Complete up-front inspection of all pump components

- Refurbishment of deteriorated components

- Upgraded replacement components

Materials upgrades

- Warranty on both service and parts

On-site installation service available

- Service for all makes and models

WASCON’s rebowl services are available for any vertical turbine pump, regardless of model, age, service or manufacture

Rebowl Services

- Reuse existing discharge head and column pipe

- Convert from packed box to mechanical seal

- Upgrade materials

- Enclosed, open or semi-open impellers, keyed or collet mounted

- Open or enclosed lineshaft construction

Bowl and enclosed impeller wear rings

- Reuse existing discharge head and column pipe

- Convert from packed box to mechanical seal

- Upgrade materials

- Enclosed, open or semi-open impellers, keyed or collet mounted

- Open or enclosed lineshaft construction

Bowl and enclosed impeller wear rings

Why Choose WASCON to Rebowl Your Turbine Pump?

WASCON exclusively uses Peerless Pump parts

WASCON stocks an extensive line Peerless bowl assemblies, impellers and bearings

Local assembly in Livingston, TN available on certain pump sizes and models

Quick turnaround on rebowls

2 weeks for bowl assemblies

4 weeks for complete pump assemblies (excluding motor)

Click Here to Download WASCON's Rebowl Brochure

WASCON stocks an extensive line Peerless bowl assemblies, impellers and bearings

Local assembly in Livingston, TN available on certain pump sizes and models

Quick turnaround on rebowls

2 weeks for bowl assemblies

4 weeks for complete pump assemblies (excluding motor)